5-AXIS HIGH PRECISION

MACHINED SOLUTIONS

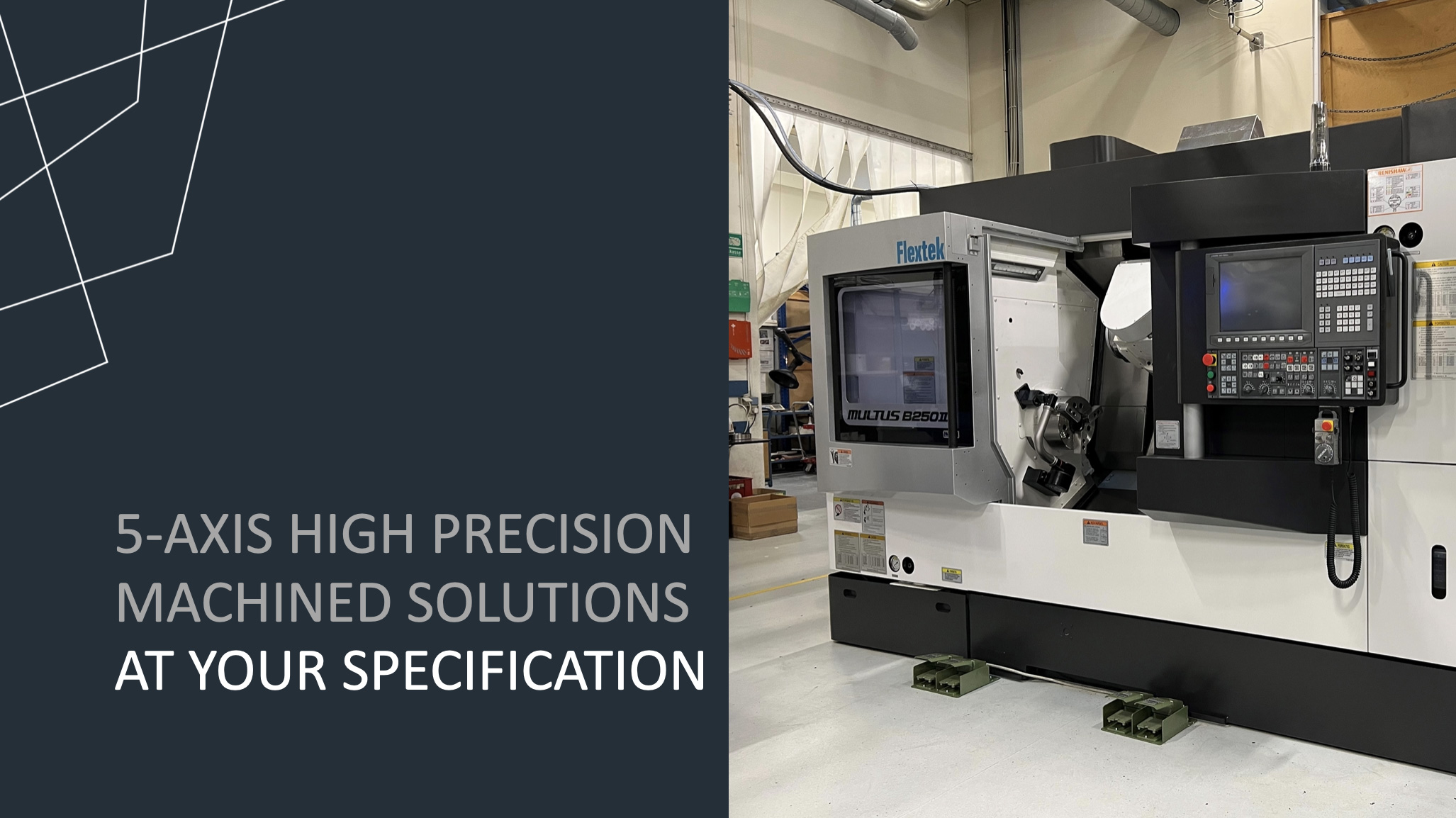

Acoplastic has a vision to provide advanced solutions in PTFE and other High-Performance plastics to leading industrial customers globally. This also means we invest in high precision 5-axis machinery with sub-spindles, which makes us capable of delivering cost effective complex high precision parts in the plastic of your choice.

THE CUSTOMER

Our customer is a global leader in water solutions. They supply intelligent, energy-saving pumps and water solutions that help provide comfort, deliver drinking water, remove wastewater or sustain crops all over the world.

They move and transform water and other liquids via intelligent, sustainable and energy-efficient solutions for use in buildings, industry and utilities.

THE CHALLENGE

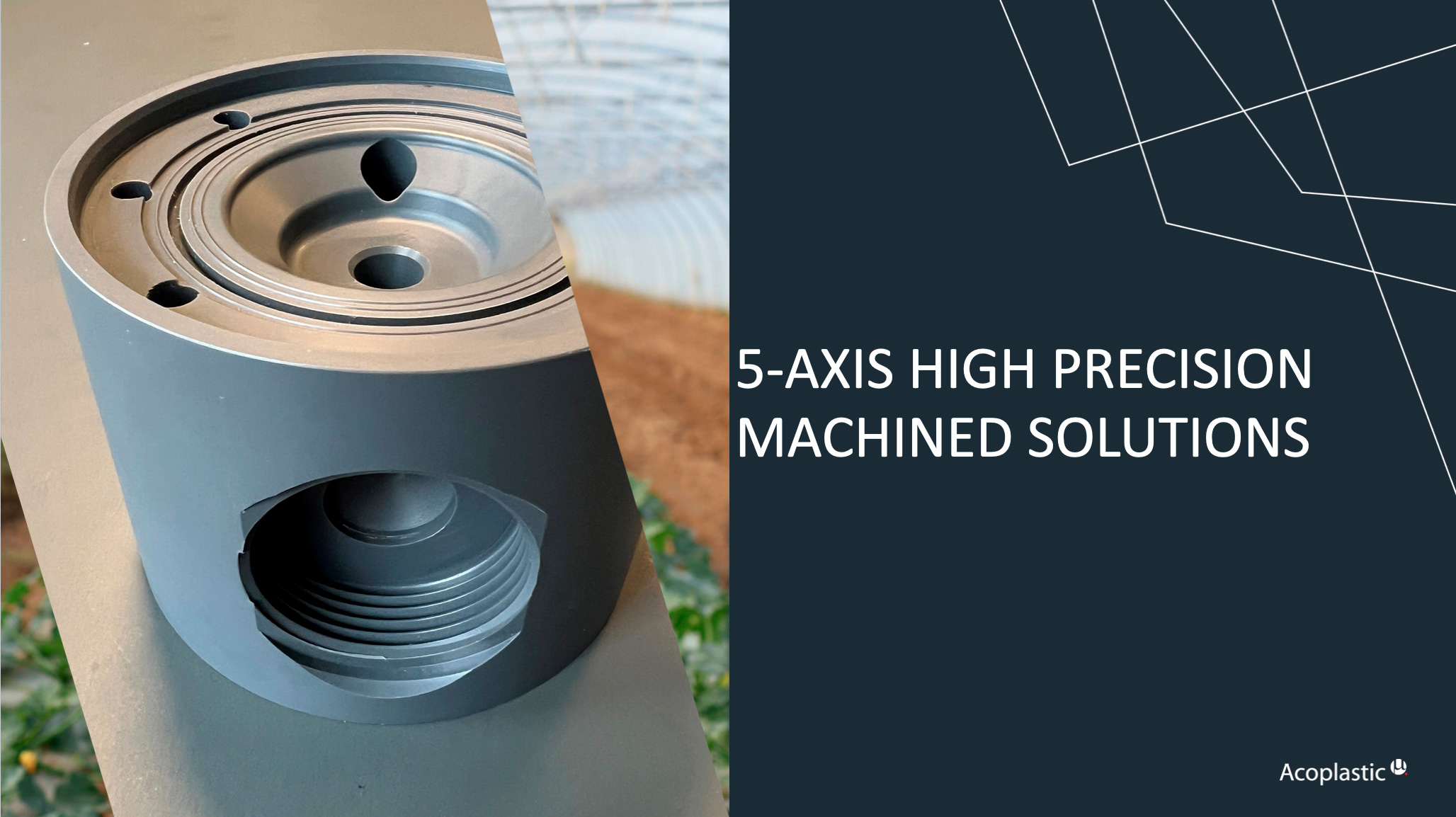

Our customer uses both injection molded and machined parts for their pump- and dosing-heads for a variety of pumps. The technical challenge of these parts is that they are complex parts with high demands on dimensional and geometric tolerances with high Cpk value requirements. In order to meet the market demand, our customer made a strategic decision to find a supplier that could be a capacity buffer on all critical pump- and dosing-head parts on a pump segment in strong growth. Quality, capacity, OTD and price competitiveness were key selection parameters.

Key challenge was to find a strategic partner/supplier that could act as a capacity buffer for a range of complex pump- and dosing-heads in PVC.

SOLUTION AND BENEFITS

Solution: In close dialogue with our customer, within a few months we developed a flexible 5-axis cost effective machine setup to meet the specifications of our customer. Acoplastic made PPAP approval process on all parts and has running business of these parts.

Benefits: The customer could go with a known supplier that was willingly to invest in a strategic supply setup to strengthen the corporation for the future and thereby secured the supply chain for pump- and dosing-heads.

5-AXIS HIGH PRECISION

MACHINED SOLUTIONS

AT YOUR SPECIFICATION