Improve total cost of ownership with a flexible supplier who handles the entire supply chain – from co-development to machined solutions in-house. The parts we manufacture will blend smoothly into your production flow and optimize the supply chain – just-in-time and in the right quality.

CO-DEVELOPMENT

Acoplastic supports our customers in developing the right part in the right quality with focus on design for manufacturing and total cost of ownership. Utilize our plastic material and manufacturing knowhow combined with our broad application and industry insight.

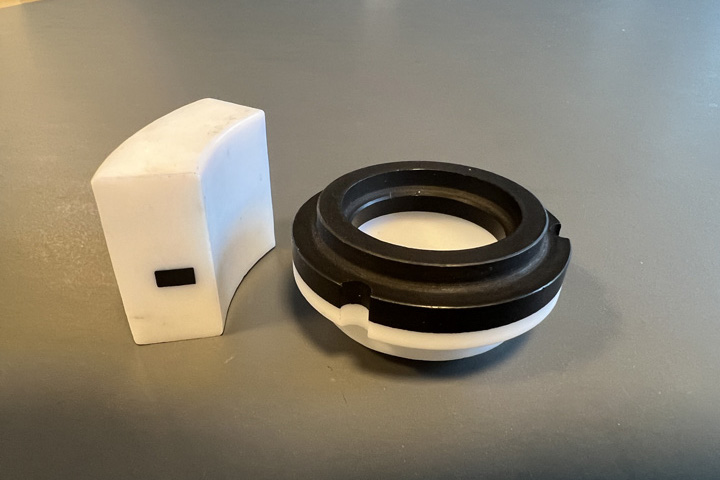

Through development projects we have among others developed the expertise in co-molding of PTFE, insert molding of PTFE and metal and insert molding of two types of PTFE e.g. a conductive element in a non-conductive material.

High volume production

Acoplastic manufactures customized plastic parts through in-house PTFE-compound mixing, -molding and -sintering, plastic machining and through our sister company Kirk Plast Complete plastic injection molding. We master a solid range of different production platforms to meet your request from a few pieces to high volume production.

Through injection molding but also machining we are able to manufacture millions of pieces every year in the right quality. We have a broad range of machines with both robotic interface and bar feeders to be a compatible supplier and partner.

Through the flexible setup in both companies, we can furthermore support our customers with assembly, marking and special packing requests.

High volume production

Acoplastic manufactures customized plastic parts through in-house PTFE-compound mixing, -molding and -sintering, plastic machining and through our sister company Kirk Plast Complete plastic injection molding. We master a solid range of different production platforms to meet your request from a few pieces to high volume production.

Through injection molding but also machining we are able to manufacture millions of pieces every year in the right quality. We have a broad range of machines with both robotic interface and bar feeders to be a compatible supplier and partner.

Through the flexible setup in both companies, we can furthermore support our customers with assembly, marking and special packing requests.

Compliance

We see a growing demand for meeting and complying with a variety of standards. We embrace and enjoy working with companies who set high requirements on documentation and compliance. Acoplastic has a skilled team to support your compliance requests. We base our declarations of conformity on data from our raw material suppliers and own tests. If your company wishes to use its own approval template, we are naturally happy to use it as the basis for our declaration.

Establish a reliable and productive solution in PTFE and high-tech plastic

Working with PTFE and high-tech plastic involves much more than just producing a machine part. It’s all about how we can refine your products and optimize your processes. We are experts in areas including material attributes, moulding, machining, quality, and documentation.

Establish a reliable and productive solution in PTFE and high-tech plastic

Working with PTFE and high-tech plastic involves much more than just producing a machine part. It’s all about how we can refine your products and optimize your processes. We are experts in areas including material attributes, moulding, machining, quality, and documentation.