5-Axis High-Precision Machining: Where Complexity Meets Accuracy

In today’s world, where components are becoming increasingly complex — both geometrically and technically — modern manufacturing methods are essential to deliver accuracy, repeatability, and flexibility. This is where 5-axis CNC machining comes in as a game-changer.

Why 5-Axis?

Traditional 3-axis machining handles many tasks efficiently. However, when parts feature complex shapes, angled surfaces, undercuts, multiple faces, or tight geometric tolerances, 3-axis machining often falls short. A 5-axis machine allows the tool and workpiece to move in multiple directions simultaneously, enabling precise machining of highly complex geometries.

This capability allows manufacturers to produce intricate parts — including contours, angles, and curved surfaces — which would be extremely difficult, if not impossible, to achieve with conventional 3-axis milling.

Advantages of 5-Axis High-Precision Machining

Exceptional Accuracy and Tolerances

5-axis machining can achieve extremely tight tolerances — essential when components must fit together precisely, such as in pump modules, dosing heads, or other technically demanding applications.

Fewer Setups, Lower Risk of Errors

Many operations can be performed in a single setup without repositioning the part multiple times. This reduces the risk of errors, minimizes changeover time, and increases production stability, and improves the possibility to meet geometric tolerances.

Complex Geometry and Flexibility

5-axis machines can approach materials from multiple angles, enabling complex designs, undercuts, angled surfaces, and compact assemblies — all critical for modern industrial applications.

Superior Surface Finish and Reduced Post-Processing

Optimal tool orientation during machining often results in smoother surface finishes, reducing or eliminating the need for polishing, grinding, or other manual finishing steps.

Cost-Effectiveness and Production Efficiency

While 5-axis machines require a significant initial investment, the benefits quickly outweigh the costs: fewer setups, higher productivity, less scrap, fewer errors, and reduced post-processing contribute to lower overall production costs.

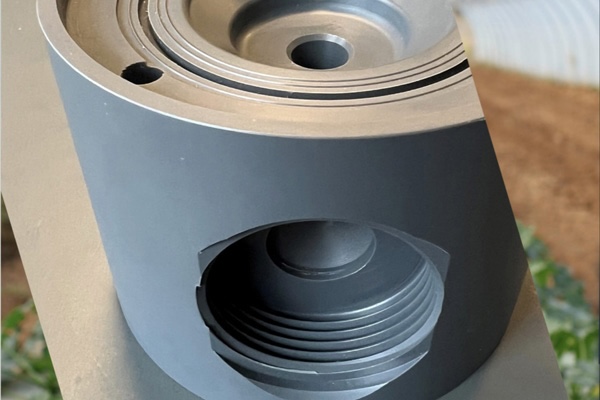

Practical Example: High-Precision Plastic Components

Some Pump manufacturers combine injection-molded and machined parts in their pumps depending on volume and complexity. The machined components demand high geometric accuracy, tight dimensional tolerances, and compliance with strict quality standards.

By investing in 5-axis machines with sub-spindles, Acoplastic delivers cost-effective, complex high-precision parts — in a wide range of different high-performance plastic materials.

The result?

A strategic setup where customers gain quality, capacity, and delivery reliability — even when facing increasing demand, complex geometries, or stringent tolerance requirements.

Why 5-Axis is the Way Forward

If your production or design requires:

• Complex geometries

• Tight geometric tolerances

• High-quality surfaces

• Design and process flexibility

• Efficiency in time, resources, and cost

…then 5-axis high-precision machining is often the right choice. It allows the production of components that would be difficult or impossible with 3-axis machining.

Conclusion: Investing in Flexibility and Quality

Adopting 5-axis machining is more than a technical upgrade — it’s a strategic investment in capabilities, flexibility, quality, and future-proof production. For companies producing complex components for e.g. pumps 5-axis machining can make the difference between good and exceptional quality.

With 5-axis high-precision machined solutions, companies can achieve lower cost per part, higher repeatability, greater design freedom, and a more robust supply chain — all while scaling production flexibly.

In a world demanding efficiency, quality, and flexibility, 5-axis machining is a powerful advantage. Are you ready to leverage it?

If you have any questions or inquiries, please feel free to contact us.