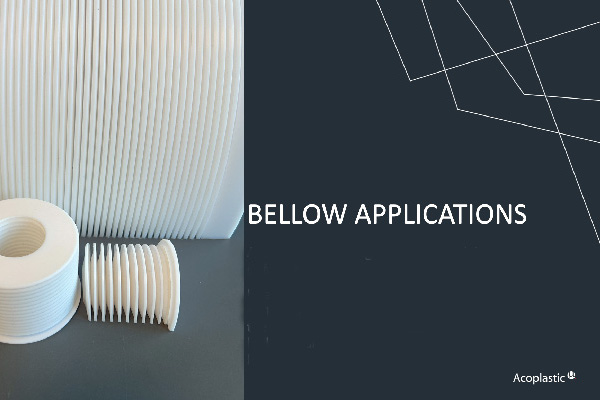

What are Bellow Applications and how to choose?

Bellow applications Acoplastic has a long history in supplying bellows for different industries and applications. It takes a lot of experience and knowledge to decide on the right design and manufacturing process to get the optimal flexibility and durability for different bellow designs. Acoplastic holds this experience and knowledge. What is Bellow Applications? Bellows…