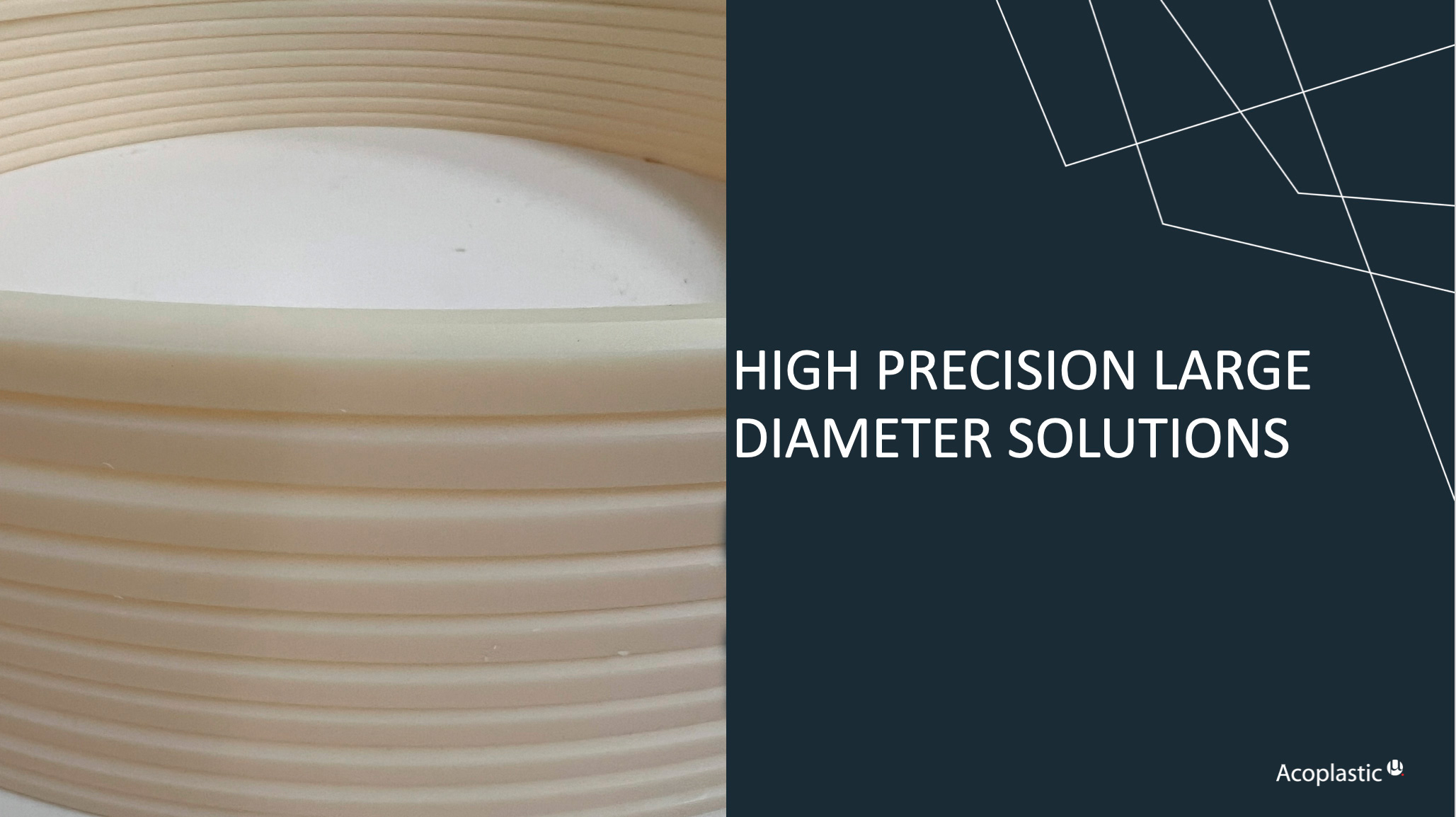

HIGH PRECISION LARGE

DIAMETER SOLUTIONS

Acoplastic has the capabilities to supply high quality turned parts up to OD 800 mm.

We furthermore have the capability to compression mold up to OD 1500 mm PTFE tubes in different Acoflon® compounds and to our customer’s specification.

THE CUSTOMER

Our customer is a leading global provider of first-rate products in the areas of heat transfer, separation and fluid handling. Based on these products our customer aims to help enhancing the productivity and competitiveness of its customers in various industries throughout the world. They define their challenges and deliver sustainable products and solutions that meet their requirements – mainly in energy, the environment, food and the marine industry.

THE CHALLENGE

Our customer has a need of various sizes of sealings in their separators for the Marine industry. They started initially with injection molded PUR seals from one of our competitors, but the quality of the molding process could not meet the geometric and surface tolerances and requirements, and the separators were leaking. By reopening the development phase of the sealing both material, design and manufacturing process was reevaluated. Since it is a marine product, the seal should work in high and low temperatures and under different humidity conditions. But it was also important to ensure that the end customer was using original spare parts.

Key challenge to find a supplier that could make a range of big seals with high surface and tolerance requirements under different climate conditions.

SOLUTION AND BENEFITS

Solution: Acoplastic could through a co-development process help to select an alternative material, provide seals with the right surface and tolerance specifications and dimension stable products through annealing. On top of this, Acoplastic introduced a marking on all seals to document the original spare part.

Benefits: Customer solved the problem with leaking separators and detection of unauthorized use of spare parts.

HIGH PRECISION LARGE

DIAMETER SOLUTIONS

AT YOUR SPECIFICATION