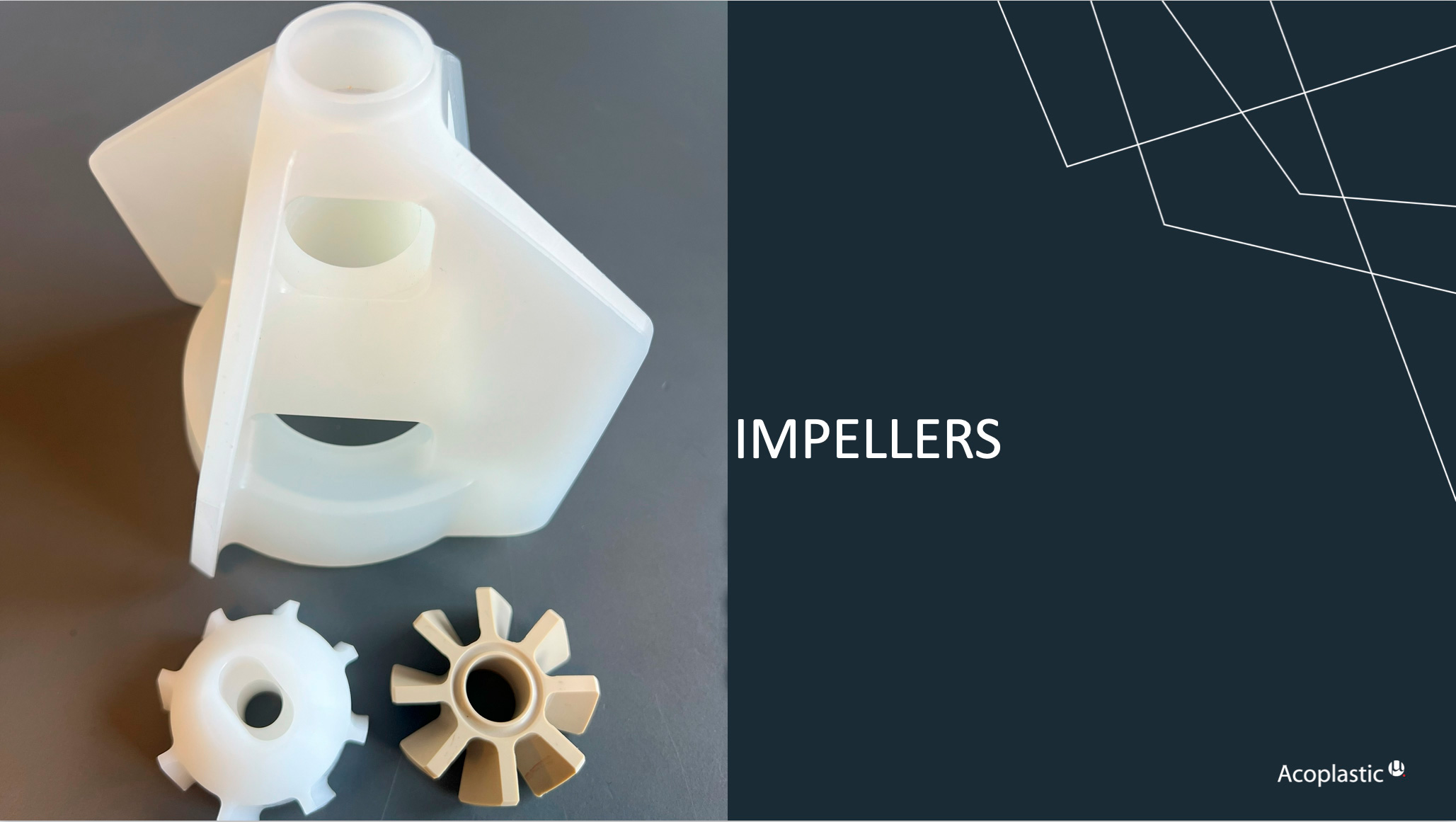

IMPELLERS

Acoplastic have over many years helped our customers with different customized plastic impellers.

Acoplastic masters the production of impellers in many different customized shapes, sizes and different plastic materials.

THE CUSTOMER

Our customer is a leading global provider of first-rate products in the areas of heat transfer, separation and fluid handling. Based on these products our customer aims to help enhancing the productivity and competitiveness of its customers in various industries throughout the world. They define their challenges and deliver sustainable products and solutions that meet their requirements – mainly in energy, the environment, food and the marine industry.

THE CHALLENGE

Our customer had a supplier that could not manufacture the existing impellers cost-effectively enough and had difficulties in meeting the new surface roughness requirements. The supplier had to machine the part in two processes. First the front then the back. This resulted in too much handling and a non-competitive process. Furthermore, the impeller was included into a new product segment where the surface requirements were increased to a surface roughness at max Ra 0,8 µm. A surface roughness that the supplier had difficulties to meet and measure.

Key challenge was to find a new supplier that could deliver the impellers with the right surface roughness and at the same time be competitive on price, quality and delivery.

SOLUTION AND BENEFITS

Solution: Acoplastic started a dialogue on how and where to measure the impellers for approval. Align the measuring method between the customer and Acoplastic. Started with qualifying production lot on our 5 axis- machine centers for PPAP approval.

Benefits: The customer now has a solution to the market with the increased surface roughness requirements and has moved the production to Acoplastic who meets all technical and commercial requirements.

IMPELLERS

AT YOUR SPECIFICATION