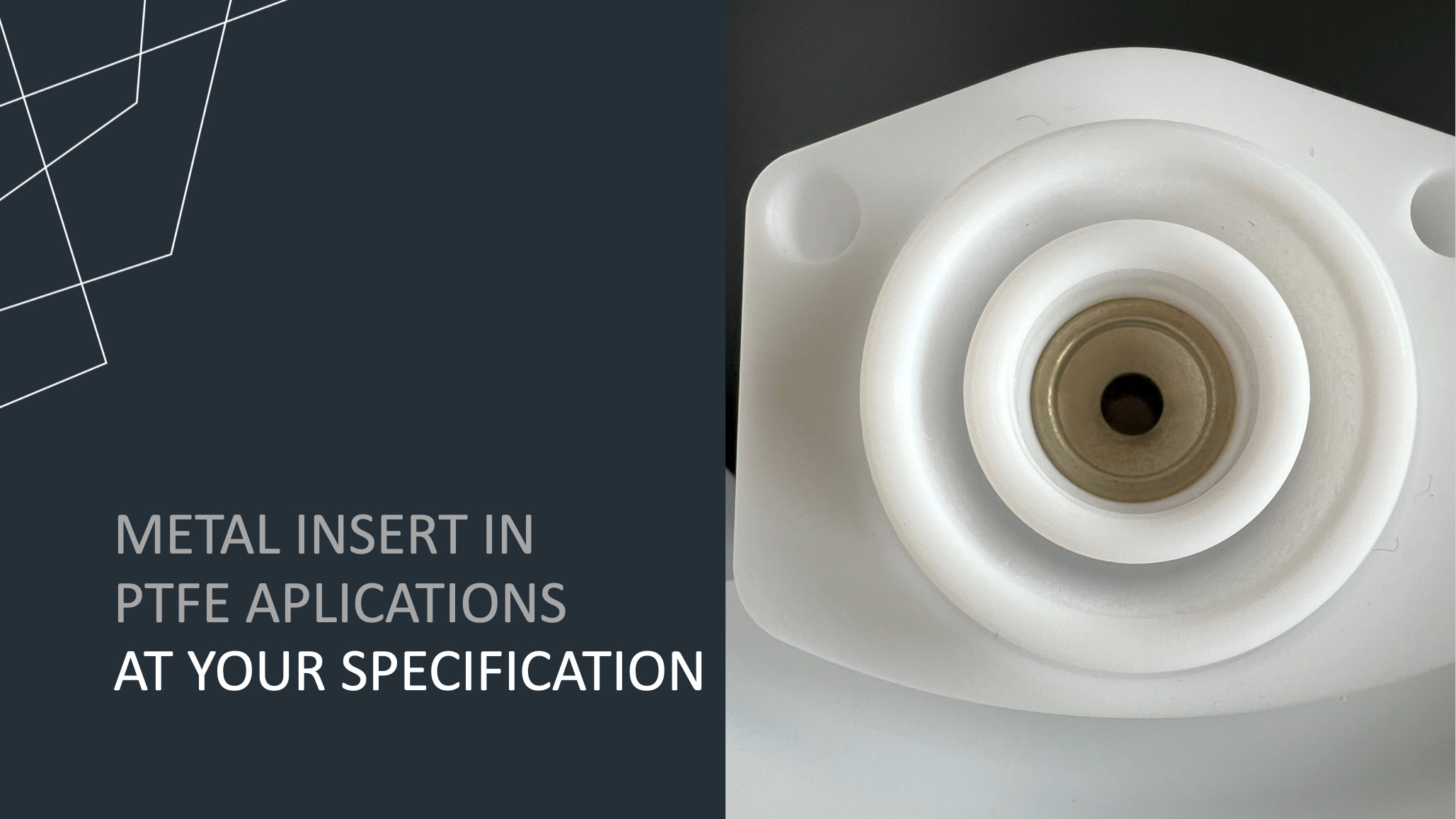

METAL INSERT

IN PTFE APPLICATIONS

Acoplastic is one of the few companies in the world which masters metal insert molding in PTFE.

Acoplastic has developed a special technique for manufacturing metal insert solutions in different PTFE compounds for various product designs and applications.

THE CUSTOMER

Our customer designs, engineers, and installs everything from turnkey process units to full-scale plants to the food and beverage industry. They have manufacturing sites, innovation centers and service centers in the Americas, Europe/Middle East, and Asia/Pacific regions.

Our customer has more than 25 Innovation and Design Centers worldwide where they design new products, develop technologies, test and optimize their critical manufacturing processes.

THE CHALLENGE

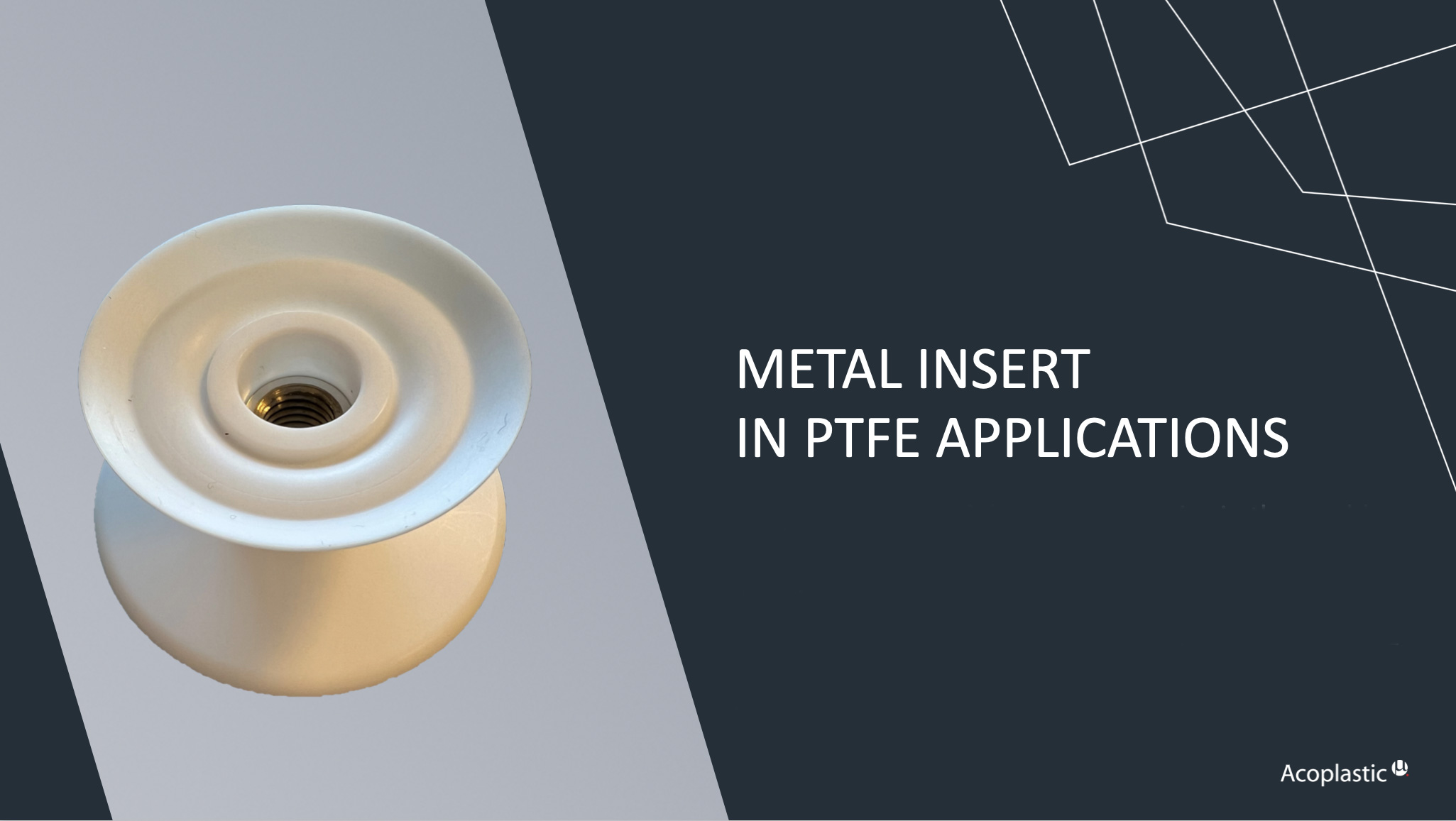

At one of our customer’s Innovation and Design Centers they were working with a product development project to improve the lifetime of one of their antiseptic valves. For this to be realized they needed to reinforce the PTFE seat strength by insert molding a metal base. However, there are not many suppliers in the world that master metal insert molding in PTFE, and they would like to avoid to increase the number of suppliers. On top of this the delivery speed from order to product was a qualifier for this project.

Key challenge was to find a supplier that promptly could help the Innovation and Design Centers to make test samples for the development project, be a sparring partner for design for manufacturing, and a possible supplier of the component at launch.

SOLUTION AND BENEFITS

Solution: Acoplastic masters, as one of a few suppliers in the world, metal insert molding in PTFE. We help the customer with on time deliveries. A service we can provide from early development phase to full scale production.

Benefits: The customer could utilize their existing supplier base, get parts on time, and the necessary sparring for design for manufacturing.

METAL INSERT

IN PTFE APPLICATIONS

AT YOUR SPECIFICATION